Top Metal Manufacure, as a Cold rolled, Galvalume steel coil manufacturer with an annual output of 50,000 tons, has been rated as a famous Cold rolled steel coil manufacturer by the Iron and Steel Association. It can customize all kinds of cold rolled steel coils and strips. We are also an excellent Cold rolled Galvanized steel coil exporter and Hot rolled steel coil Exporter.

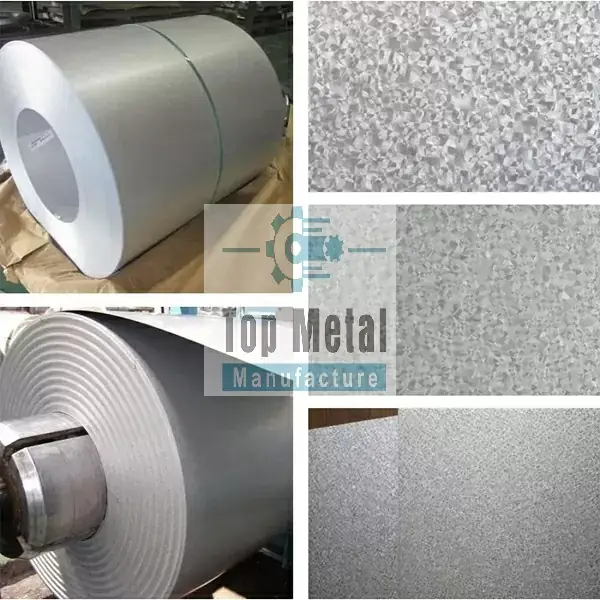

Galvalume steel is carbon steel coated with an alloy that combines the impervious properties of aluminum with the malleability and galvanic protection of zinc. The alloy coating gives galvalume steel coil and sheets a smooth, plain finish. PPGL Coil is prepared by combining Zinc Coated Steel Sheets and 55% Aluminum. The resulting product then has to be coated with Organic substances.Galvanized steel is made completely of zinc, while galvalume includes aluminum, zinc, and a small amount of silicon. This provides superior durability and resistance to corrosion in comparison to galvanized coating

As a Cold rolled, Galvalume steel coil manufacturer, our cold rolled steel coil is a steel plate that is further rolled to a target thickness at room temperature below the recrystallization temperature. Compared with hot-rolled steel plate, the thickness of cold-rolled steel plate is more accurate, and the surface is smooth and beautiful.

Hot-rolled steel coils are used as raw materials, and after pickling to remove the oxide scale, they are cold rolled. The finished product is hard-rolled coils. The cold-work hardening caused by continuous cold deformation increases the strength and hardness of the hard-rolled coils and decreases the toughness index. , So the stamping performance will deteriorate and can only be used for simple deformed parts.

The thickness of cold-rolled sheet is generally between 0.1-8.0mm, and the thickness of cold-rolled sheet produced by most factories is less than 4.5mm.

Cold rolling is processed from hot-rolled sheets at room temperature. Although the rolling process will heat up the steel plate, it is still called cold rolling. Because the hot rolling is cold rolled after continuous cold deformation, the mechanical properties are relatively poor and the hardness is too high. It must be annealed to restore its mechanical properties, and the ones that are not annealed are called rolled hard coils. Rolled hard coils are generally used to make products that do not need to be bent or stretched.

Galvanized Steel 0.18mm-20mm thick galvanized steel sheet 2mm thick Hot dip galvanized steel sizes galvanized sheet metal roll

| Thickness | 0.13-1.0mm |

| Width | 600-1500 mm |

| Zinc Coating | AZ30-150g/m2 |

| Content | 55% alu,43.5%zinc,1.5% Si |

| Surface treatment | Light Oil, oil, dry, chromate, passivated, Anti finger |

| Spangle | Minimal spangle |

| Coil Weight | 2-5 tons |

| Coil ID | 508/610 mm |

| Base metal type | Grade | CHEMICAL COMPOSITION % | |||

| C | Si | Mn | P | ||

| cold rolled steel sheet | DC51D+Z (St01Z, St02Z, St03Z) , DC51D+ZF | ≤0.10 | – | ≤0.50 | ≤0.035 |

| DC52D+Z(St04Z), DC52D+ZF | ≤0.08 | – | ≤0.45 | ≤0.030 | |

| DC53D+Z (St05Z), DC53D+ZF | ≤0.08 | – | ≤0.40 | ≤0.030 | |

| DC54D+Z (St06Z), DC54D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| DC56D+Z (St07Z), DC56D+ZF | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.025 | |

| hot rolled steel sheet | DD51D+Z (St01ZR, St02ZR) | ≤0.10 | – | ≤0.50 | ≤0.035 |

| DD54D+Z (St06ZR) | ≤0.01 | ≤0.10 | ≤0.30 | ≤0.02 | |

Steel coil is finished steel sheet or strip that has been coiled or wound after rolling with the width of the metal sheet being greater than its thickness. Steel coil with certain coatings can be weather-resistant, protect against moisture, and is ecofriendly. Steel coil is produced through different processes depending on the desired outcome.

- Steel coil is finished steel sheet or strip that has been coiled or wound after rolling with the width of the metal sheet being greater than its thickness. Steel coil with certain coatings can be weather-resistant, protect against moisture, and is ecofriendly. Steel coil is produced through different processes depending on the desired outcome.

- Hot-rolled steel coil is steel plate that is rolled at a high temperature, making the steel easier to manipulate. Due to the quick and easy process, hot-rolled steel saves time and is less expensive to manufacture.

- Cold-rolled steel coil has a nicer finish and is more durable than hot-rolled steel. Cold-rolling is a process where the steel is rolled at room temperature, below its recrystallization temperature. While cold-rolled steel coil is more superior to other coils, cold-rolled steel can be harder to manipulate due to the higher carbon content.

- Galvanized steel coil is created through a hot-dipped process that dips the metal into zinc for a nice smooth coating. The coating creates a strong rust resistance and prolongs the life of the steel coils.

- Galvannealed steel coil is created similar to galvanized steel through a hot-dipping process that soaks the metal into a liquid bath of zin alloy and then is passed through in-line heat treatment. Galvannealed steel is usually thinner and is more assessable to painting compared to other processes.