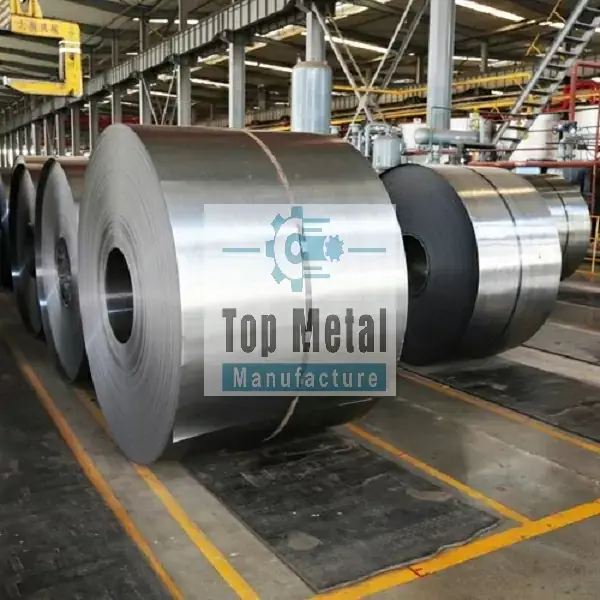

ASTM EN10310 JISI Standard carbon steel strip Cold rolled Steel strip coil CRC

Cold rolled steel sheet are mainly used in automobile, printed metal pail, building, building materials, and bicycle, etc. Additionally, it is the best material to manufacture organic coated strip.

Standard:JIS, ASTM, EN10130

Grade: SPCC, SPCD, ST12, ST13, ST14/16, DC01, DC02, DC03, DC04, DC05, DC06, Q195, Q195L,SAE1008,SAE1006

Thickness: 0.2-5.0mm

Width:15-1500mm.

(1) when the strip steel is rolled in a cold state, because of the work hardening of the strip steel, it must be softened again by intermediate annealing, and its plasticity should be restored in order to continue rolling;

(2) Before rolling, the surface scale of strip steel must be removed, thus ensuring the surface smoothness of strip steel and reducing the wear of rolls;

(3) Tension rolling is adopted, which ensures the good shape of strip steel, controls the thickness deviation of strip steel, reduces the rolling pressure, and is beneficial to rolling thin gauge products.

(4) Process cooling and lubrication are adopted, which is convenient to control the temperature of the roll and strip steel, reduce the friction between the roll and strip steel and reduce the rolling pressure, which is beneficial to the shape control and prevents the strip steel from sticking to the roll.

Cold rolled steel strip is widely used in cutting-edge technical fields, such as automobile, instrumentation, radio, national defense and aerospace industry, etc.

Cold rolled steel sheet are mainly used in automobile, printed metal pail, building, building materials, and bicycle, etc. Additionally, it is the best material to manufacture organic coated strip

Chemical Composition

DC01 steel chemical composition is listed in the following table based on ladle analysis.

| Country (Region) | Standard | Chemical Composition (ladle analysis), %, ≤ | Surface quality | Deoxidation | Classification | ||||

| Steel name (Steel number) | C | Mn | P | S | |||||

| European Union | EN 10130 | DC01 (1.0330) | 0.12 | 0,60 | 0,045 | 0,045 | A, B | Manufacturer’s discretion | Non-alloy quality steel |

| EN 10152 | DC01+ZE (1.0330+ZE) | A, B | |||||||

| EN 10139 | DC01-C390, C340, C440, C490, C590, C690 | – | |||||||

Notes:

- EN 10130 – Cold rolled low carbon steel flat products;

- EN 10152 – Electrolytically zinc coated cold rolled steel flat products.

- EN 10139 – Cold rolled uncoated low carbon steel narrow strip.

- Cold-rolled steel coils are widely applied to automobiles, electrical appliances, steel office equipment, containers, and numerous other products closely connected to pour daily lives.

| JIS G3141 Chemical Composition | |||||

|---|---|---|---|---|---|

| Material Grade | Chemical Composition % | ||||

| C | Mn | P | S | Alta | |

| SPCC | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

| SPCD | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

| SPCE | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

| for all steel grades,when C≤0.01,Alt≥0.015 | |||||

| JIS G3141 Mechanical Property | ||||||

|---|---|---|---|---|---|---|

| Steel Grade | Tensile test | r90 | n90 | |||

| Yield strength/MPa | Tensile Strength /MPa | Elongation after break b(L0=50mm, b=25mm)/% | ||||

| 0.5~1.0mm | 1.0~2.0mm | not less than | ||||

| SPCC | 140~280 | ≧270 | ≧34 | ≧37 | ||

| SPCD | 140~240 | ≧270 | ≧36 | ≧39 | 1.3 | |

| SPCE | 130~210 | ≧270 | ≧38 | ≧41 | 1.6 | 0.18 |