Galvanized steel coil is a type of steel coil that has been coated with a layer of zinc to protect it from corrosion.

The process of galvanizing involves applying a thin layer of zinc to the surface of the steel coil by immersing it in a bath of molten zinc. The zinc coating provides a barrier between the steel and the surrounding environment, preventing rust and corrosion from developing.

Galvanized steel coils are commonly used in a variety of applications, including construction, automotive manufacturing, and household appliances. They are known for their durability, strength, and resistance to corrosion.

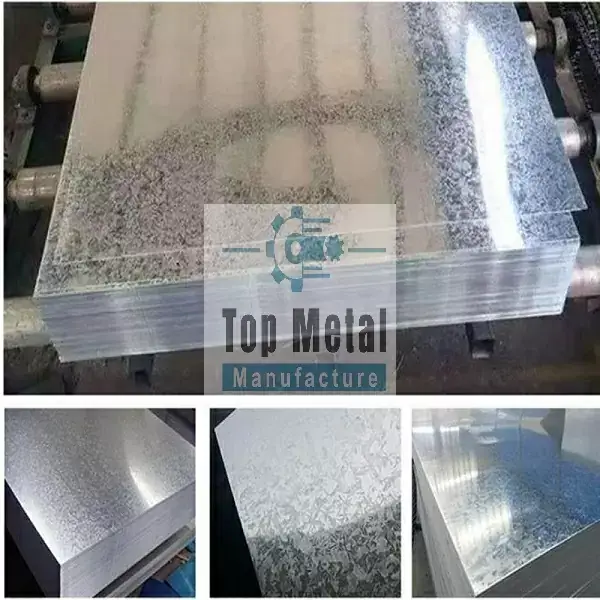

China Manufacturer JIS ASTM DX51D AZ150 Galvalume Cold Rolled Sheets Coils Hot Dip SGCC Z275 Galvanized Steel Strip GL GI

Galvanized sheet refers to the steel plate coated with a layer of zinc. Galvanizing is an economical and effective antirust method which is often used. About half of the world’s zinc production is used in this process.

Galvanized Steel Coils have gone through a chemical process to keep them from corroding. The steel gets coated in layers of zinc because rust won’t attack this protective metal. For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. The principal method of making steel resist corrosion is by alloying it with another metal, zinc. When steel is submerged in melted zinc, the chemical reaction permanently bonds the zinc to the steel through galvanizing. Therefore, the zinc isn’t exactly a sealer, like paint, because it doesn’t just coat the steel; it actually permanently becomes a part of it.

TOP Metal Manufacture is a professional manufacturer and supplier of Hot Dip Galvanized Steel Strip with high quality and reasonable price

For galvanized steel coils, the steel sheet is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ℃ to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.

| Product Name | Galvanzied Steel Coil, Galvalume Steel Coil, Zinc coated coil, Aluzinc Strip Coil, GI, GL, HDGI, HDGL |

| Standard | EN10147, EN10142, DIN 17162, JIS G3302, ASTM A653 |

| Steel Grade | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490,SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340 , SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); or As Requirement |

| Type | Coil/Sheet/Plate/Strip |

| Material | CGCC/SGCH/G350/G450/G550/DX51D/DX52D/DX53D |

| Thickness | 0.12mm-4.0mm or 0.8mm/1.0mm/1.2mm/1.5mm/2.0mm |

| Width | 600mm-1500mm or 914mm/1000mm/1200mm/1219mm/1220mm |

| Zinc Coating | Z30g/m2-Z350g/m2 |

| Surface Structure | Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS) |

| Coil Weight | 3 Tons -8Tons |

| Coil ID | 508mm/610mm |