Equivalent Grade : AISI H11,SAE H11, H11, 4Cr5MoSiV, DIN 1.2343, JIS SKD6 ,DAIDO SKD6 BOHLER W300

| Material | 1.2343 (Chemical Compositions %) | |||||||

| C Si Mn Cr Mo V P & S | ||||||||

| 0.36-0.42 0.90-1.20 0.30-0.50 4.80-5.80 1.10-1.40 0.25-0.50 ≤0.030 | ||||||||

| Size | Round φ20-650mm; Flat 20-450x50-810mm | |||||||

| Origin Place | Made in China | |||||||

| Delivery Condition | Forged/hot rolled | |||||||

| Surface Treatment | Black/grinded/peeled/turned/milled/polish/bright | |||||||

| Heat Treatment | Annealed 2-4 times | |||||||

| Packing | Seaworthy packing or as per client's request | |||||||

| MOQ | 10Ton | |||||||

| Delivery Time | 60 Days | |||||||

| Trade Term | FOB/CIF/CFR | |||||||

| Payment Term | T/T | |||||||

| Loading Port | Shanghai | |||||||

H11 tool steels are forged at 900- 1120°C .Reheat is necessary when temperature below 900°C ,AISI H11 steel should be cooled as slowly as possible in the furnace,annealing is recommended after forged. Stress relieving to remove machining stresses should be carried out by heat to 650°C, holding for one hour at heat, cooling in the furnace.

The forming characteristics of H-11 H11 AMS 6487 Tool Steel are good by conventional methods. It also may be formed by forging and machining. Welding H-11 AMS 6487 Tool Steel is a readily wieldable alloy by conventional methods.

Tool Steel H11 has minimal distortion during deep-hardening and air-hardening thanks to the balanced alloy content. H11 can also be hardened with an air quenching method

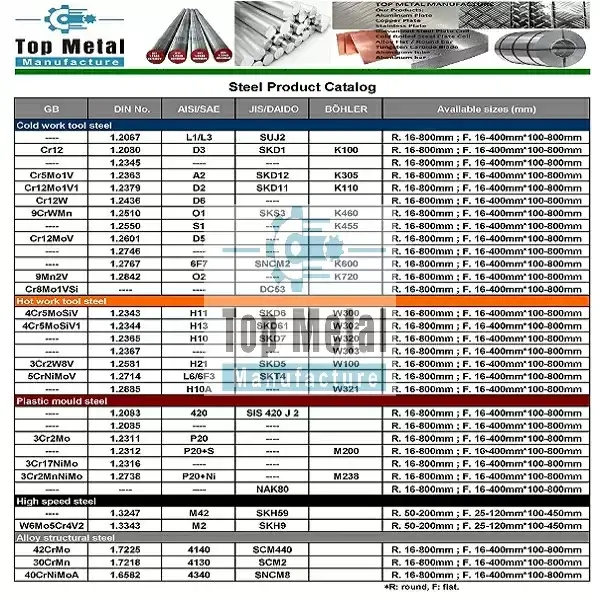

| Hot work tool steel | |

| DIN | 1.2344,1.2343,1.2365,1.2581,1.2367,1.2714 etc. |

| AISI | H13,H11,H10,H21,L6 etc. |

| JIS | SKD61,SKD6,SKD5,SKT4 etc. |

| Cold work too steel | |

| DIN | 1.2601,1.2379,1.2080,1.2363,1.2842,1.2419,1.2510,1.2550,1.2767 etc. |

| AISI | D2,D3,A2,O2,O1 etc. |

| JIS | SKD1,SKD11,STD12,SKS31,SKS3 etc. |

| Plastic mould steel | |

| DIN | 1.2083,1.2311,1.2312,1.2316,1.2738 etc. |

| AISI | P20, P20+Ni,P20+S,420 etc. |

| JIS | NAK80 |

Other Tool steel materials available