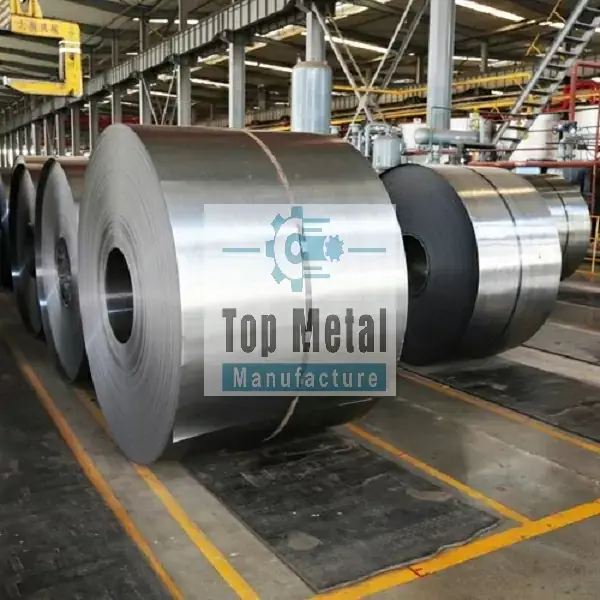

EN 10130 DC01 Steel 1.0330 cold rolled steel flat sheet coil

DC01 steel (1.0330 material) is a European standard cold-rolled quality low-carbon steel flat product for cold forming. In BS and DIN EN 10130 standard, it contains 5 other steel grades: DC03 (1.0347), DC04 (1.0338), DC05 (1.0312), DC06 ( 1.0873) and DC07 (1.0898), the surface quality is divided into 2 types: DC01-A and DC01-B. In addition, this steel is also used under electrogalvanizing conditions. The designation of the steel is DC01+ZE (or 1.0330+ZE), and the standard is EN 10152.

DC01 Meaning and Definition

- D: (Drawing) flat products for cold forming

- C: Cold rolled

- DC01: Drawing quality

- DC03: Deep drawing quality;

- DC04, DC05: Special deepdrawing quality;

- DC06: Extra deepdrawing quality;

- DC07: Super deep drawing quality.

Chemical Composition

DC01 steel chemical composition is listed in the following table based on ladle analysis.

| Country (Region) | Standard | Chemical Composition (ladle analysis), %, ≤ | Surface quality | Deoxidation | Classification | ||||

| Steel name (Steel number) | C | Mn | P | S | |||||

| European Union | EN 10130 | DC01 (1.0330) | 0.12 | 0,60 | 0,045 | 0,045 | A, B | Manufacturer’s discretion | Non-alloy quality steel |

| EN 10152 | DC01+ZE (1.0330+ZE) | A, B | |||||||

| EN 10139 | DC01-C390, C340, C440, C490, C590, C690 | – | |||||||

Notes:

- EN 10130 – Cold rolled low carbon steel flat products;

- EN 10152 – Electrolytically zinc coated cold rolled steel flat products.

- EN 10139 – Cold rolled uncoated low carbon steel narrow strip.

- Cold-rolled steel coils are widely applied to automobiles, electrical appliances, steel office equipment, containers, and numerous other products closely connected to pour daily lives.

| JIS G3141 Chemical Composition | |||||

|---|---|---|---|---|---|

| Material Grade | Chemical Composition % | ||||

| C | Mn | P | S | Alta | |

| SPCC | ≤0.12 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

| SPCD | ≤0.10 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

| SPCE | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

| for all steel grades,when C≤0.01,Alt≥0.015 | |||||

| JIS G3141 Mechanical Property | ||||||

|---|---|---|---|---|---|---|

| Steel Grade | Tensile test | r90 | n90 | |||

| Yield strength/MPa | Tensile Strength /MPa | Elongation after break b(L0=50mm, b=25mm)/% | ||||

| 0.5~1.0mm | 1.0~2.0mm | not less than | ||||

| SPCC | 140~280 | ≧270 | ≧34 | ≧37 | ||

| SPCD | 140~240 | ≧270 | ≧36 | ≧39 | 1.3 | |

| SPCE | 130~210 | ≧270 | ≧38 | ≧41 | 1.6 | 0.18 |